The Challenge Today

Inventory teams spend countless hours tracking stock levels, managing supplier responses, and adjusting replenishment plans manually. Disconnected systems, inconsistent forecasts, and reactive order handling lead to overstocking, stockouts, and missed opportunities. The result: rising carrying costs, delayed production, and planners stuck in spreadsheets instead of focusing on strategic supply management.

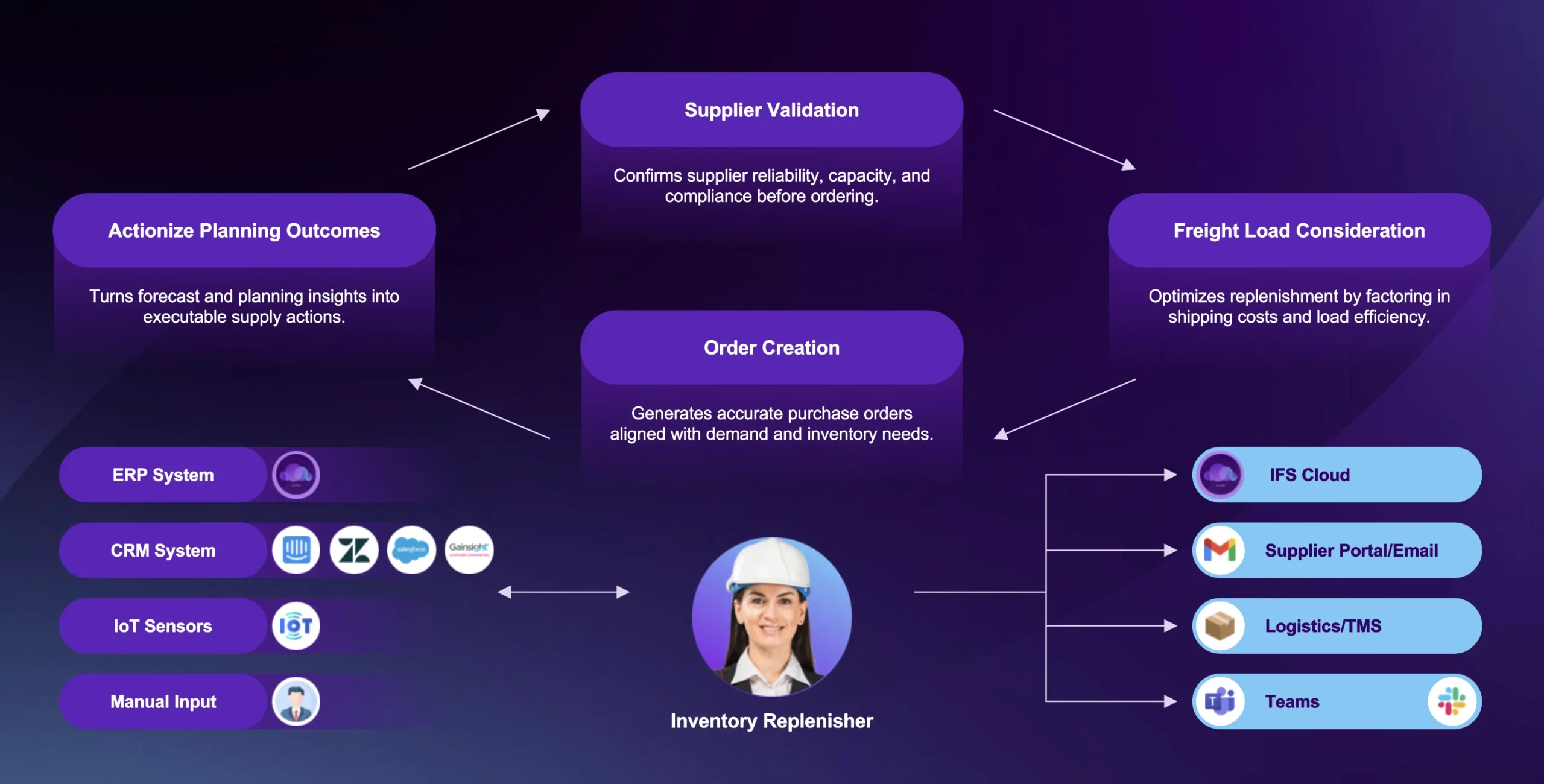

How It Works

The Inventory Replenisher Digital Worker turns manual, reactive replenishment into an intelligent, autonomous process that ensures material availability while optimizing cost.

-

Forecast demand: Predicts future inventory needs using sales, seasonality, and external data.

-

Select supplier: Chooses the best internal or external source using reliability and cost metrics.

-

Generate and track POs: Drafts, submits, and updates purchase orders automatically.

-

Handle exceptions: Flags forecast deviations, delays, or shortages for planner review.

-

Coordinate delivery: Ensures timely shipment and inbound visibility with logistics updates.

-

Recommend replenishment: Suggests optimal order quantities and timing based on service targets and lead times.

Smarter Inventory Replenishment

What This Worker Uses:

Microsoft Outlook

Gmail

CRM

Salesforce

ServiceNow

Hubspot

ERP

IFS

Microsoft Dynamics

Collaboration

Slack

Microsoft Teams

Microsoft Outlook

Documents

IFS

Google Drive

Key Problems Solved

Reduces stockouts and excess inventory through predictive planning.

Eliminates repetitive, manual order management tasks.

Improves supplier reliability and replenishment speed.

Enhances visibility across warehouse, ERP, and supplier data.

Frees planners to focus on exceptions and strategic decisions.

Business Value and Impact

- Higher availability – Proactively prevents shortages and disruptions.

- Lower costs – Optimizes inventory carrying and ordering expenses.

- Greater efficiency – Automates 30–40% of planner workload.

- Improved supplier performance – Strengthens on-time delivery and accuracy.

- Scalable – Adapts across product lines, geographies, and supply models.

Why It Matters

The Inventory Replenisher Digital Worker brings intelligence and stability to the heart of your supply chain, ensuring the right materials are available at the right time, with minimal waste and maximum efficiency. It transforms replenishment from reactive firefighting into proactive, data-driven control.